Designing ‘An Introduction to Braille’

Braille printing

I used two types of braille printing for the book and integrated this with full color offset. Not only an interesting production process but also one with extra steps. Before the braille could be printed all the sheets were first printed in offset and then partly finished: trimmed, creased, folded and then opened out flat again; the back cover was first die-cut before being glued.

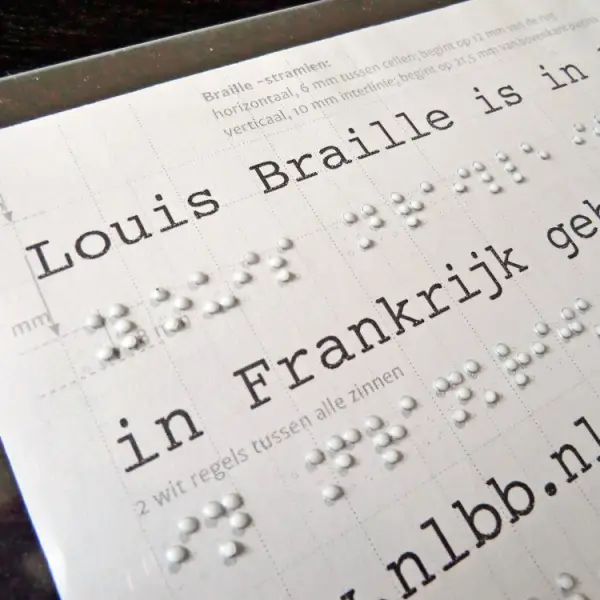

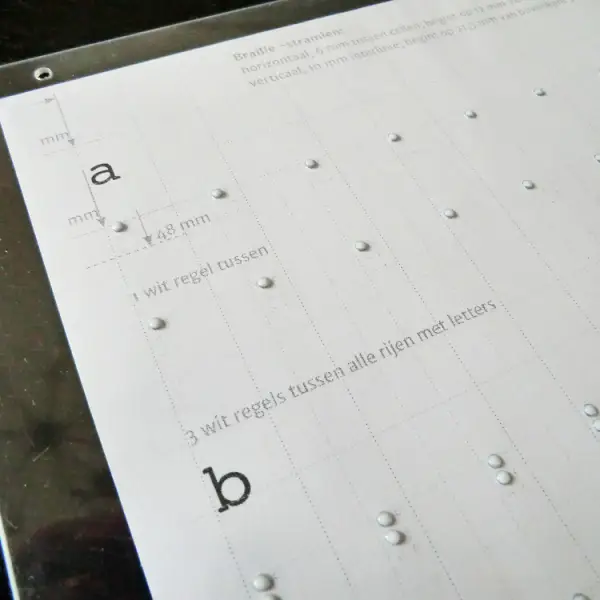

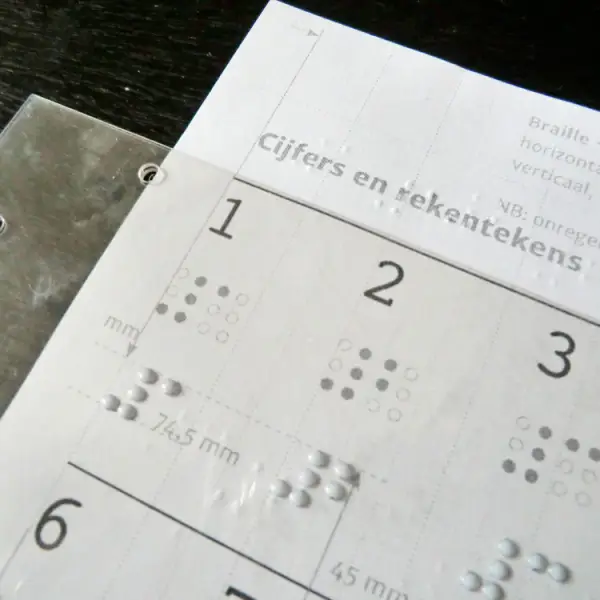

Instructions for Braille

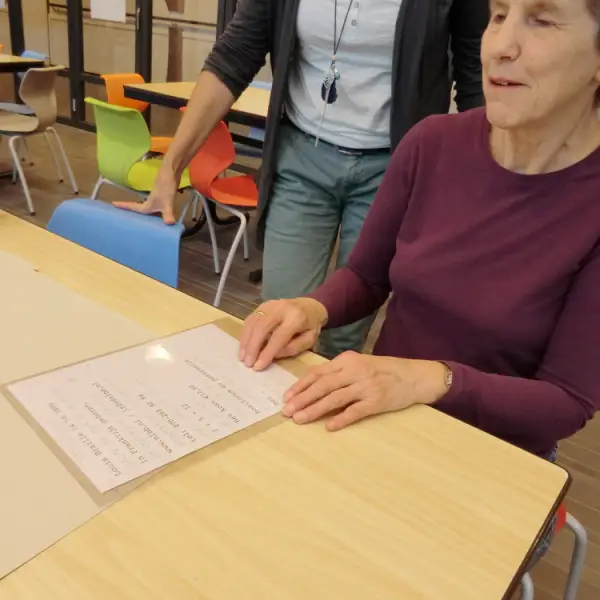

In preparation for making the braille plates I provided detailed instructions showing the positioning of the braille in relation to the printed text. Where possible I used standard braille line spacing (10 mm), making it easier to generate the plates. When they were ready, I checked them thoroughly with the other members of the group, ensuring that the braille was correct. Furthermore, I made regular visits to the braille printers, checking the sheets as they came off the press.

Braille printing plates with instructions

Braille ‘Embossing’ on the Cover

Due to the printsize and the paper thickness the braille on the cover was ‘embossed’. As the name would suggest, this was done on a Braille Embosser (The Marburg Embossing Machine), which can even emboss braille on metal. It can be used with paper from roughly 200 grams onwards (if the paper is too light, the machine literally punches the dots through the paper). It produces braille of a very high standard. The only disadvantage is that each printed sheet has to be positioned and embossed manually – in this case two and a half minutes per sheet, and then more than a thousand times!

The embosser can be used both widthwise and lengthwise, which means that it is possible to work with irregular sizes and large sizes. However the maximum plate size is limited which means that, in some cases, it is necessary to emboss braille in parts. When making the printing proofs the lower rows of dots (dots 3 and 6) fell just outside the embossing field; after making some slight adjustments to the films this was resolved.

Braille ‘Printing’ in the Interior

The braille was printed on the inside pages in a traditional way using a Heidelberg Flatbed Press. The maximum printing size available was A3 and a paper weight up to approximately 200 grams. Unlike standard braille printing jobs, this book was more complex. The braille printwork was two-sided, using the maximum trimmed printing size. Furthermore the integration with offset printing meant that the position of the braille had to be exact.

Achieving a constant pressure overall was important for the quality of the braille. In practice this turned out to be quite a challenge, partly because the amount of braille on each pages was so different: everything between 3 characters in braille and whole sentences in braille. The plates had to be adjusted manually (extra padding in certain places) and regularly replaced because the dots wore down quickly.